What is Bill of Material (BoM)?

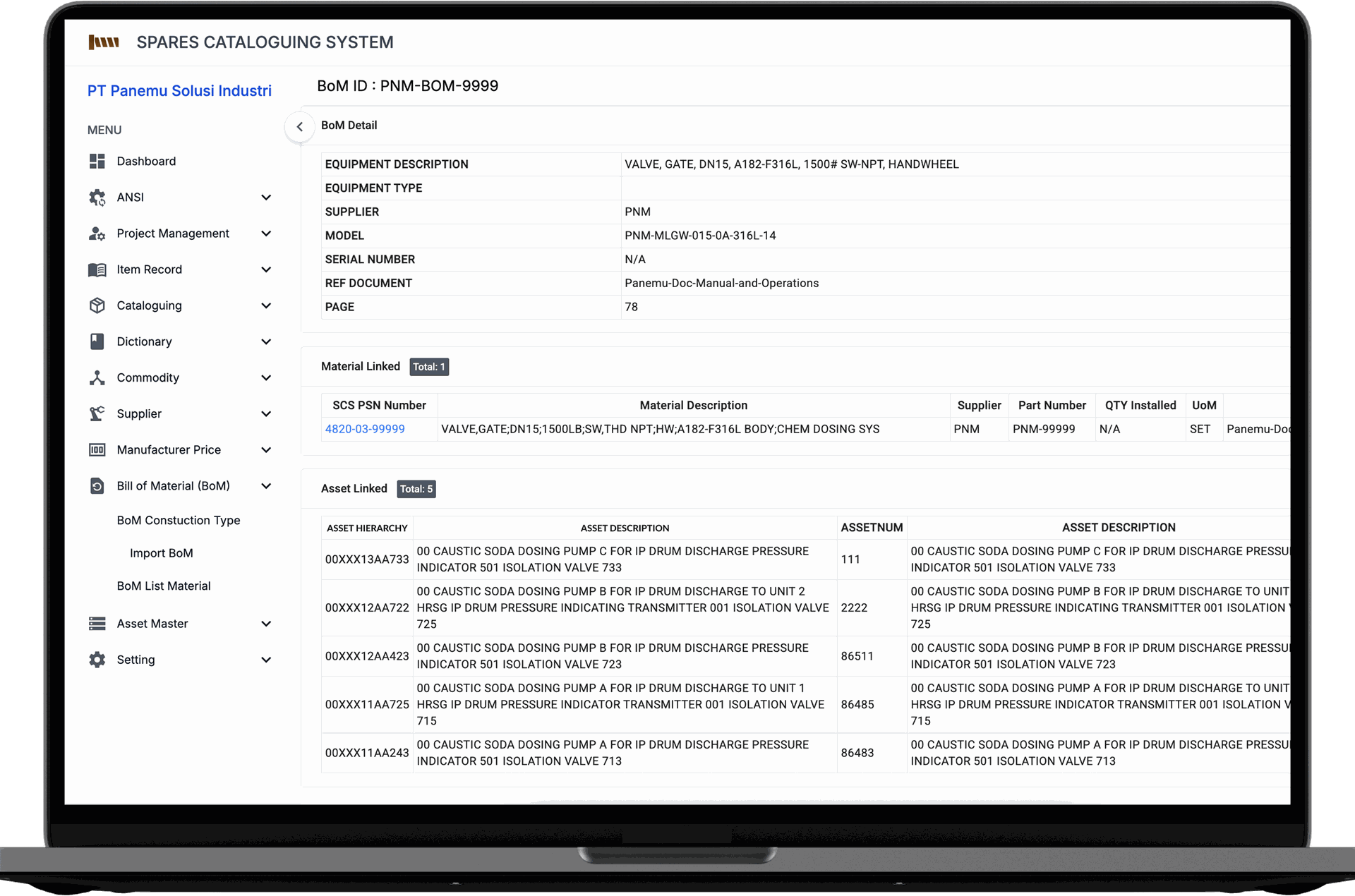

A Bill of Material (BoM) lists all components, sub-assemblies, and spares needed to build, maintain, or repair assets, showing clear parent-child relationships linked to equipment tags and locations. Panemu transforms raw data into production-ready BoMs compliant with UNSPSC, KKS, NATO/NSN, and ISO standards, formatted for direct SAP, Oracle, or Maximo import.

Why Choose Panemu for BoM?

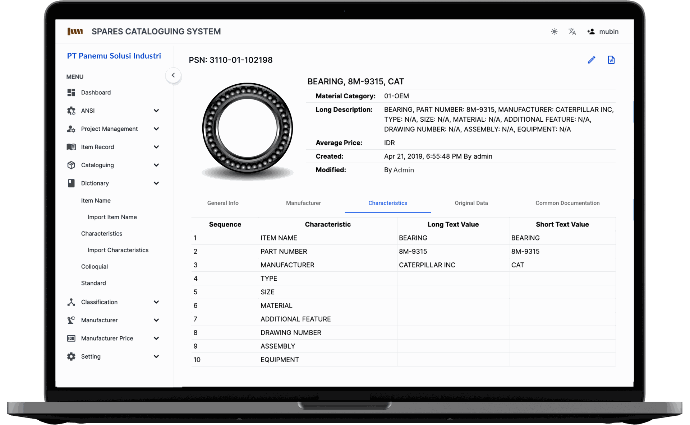

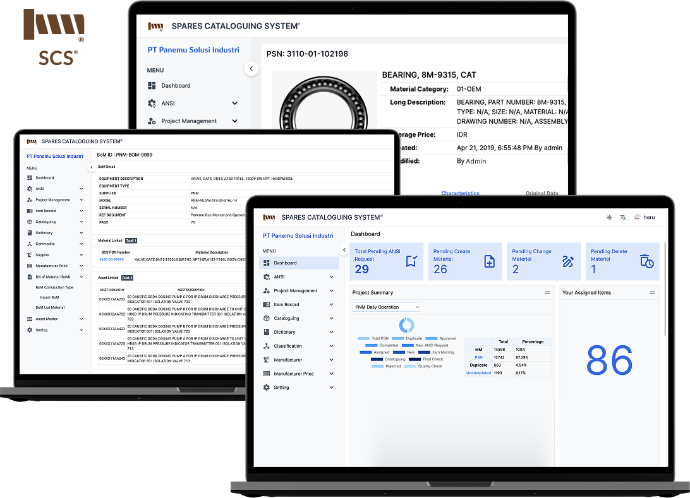

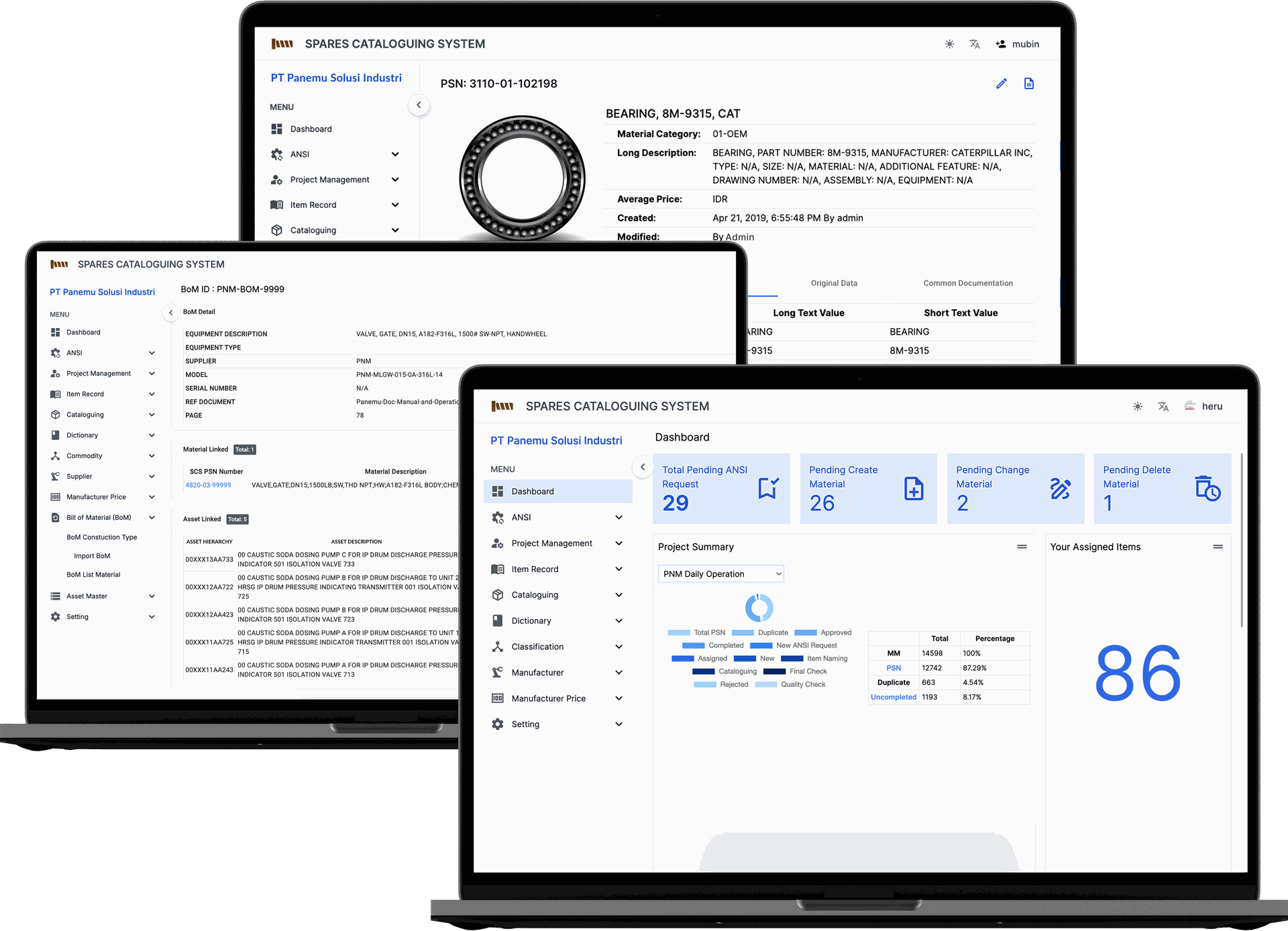

We provide end-to-end Bill of Material (BoM) development and validation powered by our Spares Cataloguing System (SCS), which includes a fully integrated BoM module. This ensures your BoM is not only accurate and complete, but also directly connected with your Material Master Data for seamless management and operational efficiency. Our experts apply industry best practices, standardized naming conventions, and structured asset hierarchies to deliver BoMs that integrate effortlessly with your ERP or EAM platforms. Supported by SCS’s powerful data engine, our BoM service becomes significantly more efficient, reliable, and scalable.

Our BoM Cataloguing Service

Panemu specializes in professional BoM development and validation:

- Data Cleansing: remove duplicates and standardize descriptions.

- Hierarchy Building: create multi-level structures from technical drawings and manuals.

- Asset Linking: connect BoMs with equipment tags and functional locations.

- Standards Compliance: apply NATO, UNSPSC, KKS, ISO, and manufacturer codes.

- Alternate Parts Mapping: identify substitute and superseded items.

- ERP Preparation: ready for direct import into SAP, Oracle, or Maximo.

The service uses proprietary tools for quality control and delivers clean, validated BoMs ready for production use.

BoM Integrated with SCS

Panemu's Bill of Material service is powered by our Spares Cataloguing System (SCS), creating a seamless connection between asset hierarchies and clean material master data.

Key Integration Benefits:

- Single Workflow: Build BoMs and material masters simultaneously, no data transfer errors

- Live Validation: SCS checks parent-child relationships against material catalog in real-time

- Multi-Level Sync: Changes to base materials automatically update all related assemblies

- ERP One-Click Export: Complete BoM + materials package formatted for SAP/Oracle/Maximo

- Version Control: Track BoM revisions with full material audit trail

How It Works:

RAW Data

SCS® Cleansing

Deduplications

Material Master

Validated

Bom Hierarchy

Linked

ERP Import

Ready

Typical timeline: 6-12 weeks based on asset volume.

Common BoM Challenges

Unstructured Bill of Material (BoM) data undermines maintenance,

inventory, and procurement processes, creating high error risks. Without

clear structure and standardization, operational costs rise, downtime

extends, and ERP systems cannot perform optimally.

Problem

|

Impact

|

Duplicate parts

|

20-30% excess inventory

|

Incomplete hierarchies

|

Wrong kitting, repair delays

|

Site inconsistencies

|

No company-wide visibility

|

Poor ERP data

|

Manual fixes waste weeks

|

Excel-only tracking

|

No version control

|

COMPLETE MATERIAL CATALOGUING TOOLS

SPARES CATALOGUING SYSTEM™

SCS™ is Panemu's specialized platform for material cataloguing and data management. Designed for asset-intensive operations, it provides structured workflows for data cleansing, standardization, and ERP preparation. SCS™ helps maintain consistent material master data across teams and sites.

Key SCS Features:

Structured workflows for step-by-step cataloguing with quality checkpoints

Multi-user role-based access for warehouse, planners, and procurement teams

Various dictionaries (UNSPSC, NATO/NSN, manufacturer codes)

Multi-project support for different sites, plants, or equipment fleets

Customizable fields to match your specific standards and processes

Direct ERP exports (SAP, Oracle, Maximo, Odoo) with validated templates

Cloud-based access for remote teams with high availability

Alternate parts tracking and superseded item management

We are trusted by

-

And many more -

Schedule Free Consultation

Share your requirements or inquiries with us.

Our team is ready to provide professional support and tailored solutions aligned with your operational standards.

Email :

Phone/Whatsapp :

Head Office :

Jl. Panemu No. 01, Kalisoka, Margosari, Kec. Pengasih, Kab. Kulon Progo, Daerah Istimewa Yogyakarta 55652