In managing the company's inventory, the supply cataloging system plays a crucial role in organizing and managing goods data efficiently. This process involves the use of rules that are important for inventory data to be well organized and standardized. In this article, we will explain some important rules in the supply cataloging system that must be understood by inventory managers and decision makers within the company. By understanding and applying these rules, you can ensure effectiveness, efficiency and success in managing your company's inventory.

BUILD BEST QUALITY INVENTORY DATA FOR YOUR INVENTORY

Rule 1: Use of International Standards

It is important for companies to use international standards in their supply cataloging system. One of the commonly used standards is the NCS (NATO Codification System) and UNSPSC (United Nations Standard Products and Services Code) numbering standards. This standard helps in searching, classifying, and replacing items more efficiently. By adopting international standards, companies can ensure uniformity and consistency in inventory data management.

Rule 2: Consistency of Item Numbering and Classification

Consistency in the numbering and classification of goods is very important in a supply cataloging system. Companies must adopt clear and consistent rules for numbering and classifying goods according to established standards. This facilitates the identification, search, and grouping of goods, and minimizes errors and data duplication.

Rule 3: Data Update and Maintenance

The data in the supply cataloging system must be updated regularly and properly maintained. Inventory managers need to maintain data integrity by updating item information, adding or removing irrelevant items, and monitoring changes that occur. The process of updating and maintaining regular data will ensure that inventory information remains accurate, up-to-date and reliable.

I NEED HELP TO CLEAR DUPLICATED DATA IN MY INVENTORY DATA

Rule 4: Involvement of a Qualified Cataloger Team

It is important to involve a team of catalogers who are reliable and experienced in supply cataloging systems. The cataloger team has the knowledge and expertise in identifying product categories, classifying items correctly, and compiling a structured list of items. With the help of a reliable team of catalogers, companies can ensure that inventory data is managed properly and according to predetermined rules.

Rule 5: Implement a Verification and Validation Process

The process of verification and validation is an important step in the supply cataloging system. Companies need to adopt mechanisms that ensure the accuracy and validity of inventory data. This process involves periodically reviewing and checking data to ensure that the information provided is accurate, complete, and conforms to established standards.

Rule 6: Use of Data Analysis Tools

The use of data analysis tools plays an important role in supply cataloging systems. Companies need to utilize the right analytical tools to analyze inventory data, identify product usage trends, optimize inventory, and make decisions based on accurate data. By using the right analytical tools, companies can increase efficiency, reduce costs, and optimize inventory management.

GET THE BEST APPS TO BUILD ACCURATE INVENTORY DATA

In the company's supply cataloging system, understanding and applying the relevant rules is very important. By using appropriate international standards, maintaining consistency in the numbering and classification of goods, updating and maintaining data regularly, involving a reliable team of catalogers, implementing verification and validation processes, and utilizing data analysis tools, companies can optimize inventory management, improve efficiency, and make better decisions.

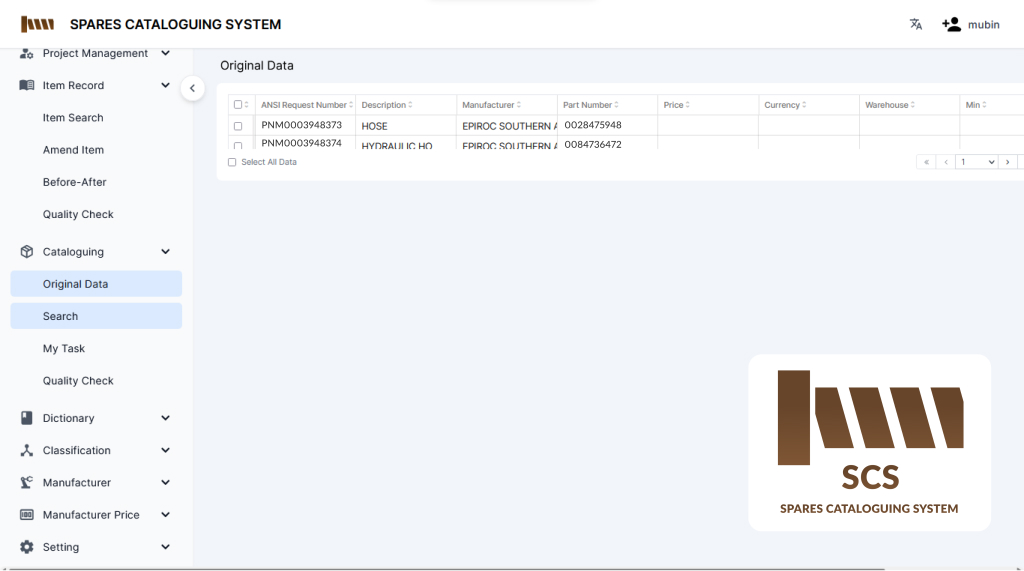

As an effective solution to overcome the challenges of supply cataloging systems, Panemu comes with the best solution, namely the SCS (Spares Cataloging System) application. This application is specifically designed to help companies manage inventory data more efficiently and accurately. With SCS, you can easily enforce international standards, clean up duplicate data, and maintain a neat data structure. In addition, this application also allows the application of the numbering and classification of goods according to the NCS and UNSPSC numbering standards. With the support of a reliable team of catalogers owned by Panemu, you can ensure that the company's supply cataloging process runs smoothly and efficiently.

Get more important information for your business :

Practical Steps to Begin the Supply Cataloging Process Understanding Supply Cataloging: An Important Foundation in Supply Chain Management Get to know the Dual Scale Payroll System: Advantages and Challenges How to Calculate Salary with a Single Scale Payroll System

Not only that, Panemu also offers consulting services and comprehensive technical support in inventory management and supply cataloging. An experienced team is ready to assist you in dealing with problems that may arise, provide tips and tricks, as well as the right solutions according to your company's needs.

So, if you are looking for the best solution to optimize the supply cataloging process in your company, Panemu with its SCS application is the right choice. Benefit from Panemu's experience in this field and increase the efficiency and success of your company's inventory management.

Thank you for reading this article. If you want to know more about the SCS application and the services offered by Panemu, please visit our website at www.panemu.com or contact us directly via the contact listed.

CONTACT PANEMU TEAM TO CONSULT