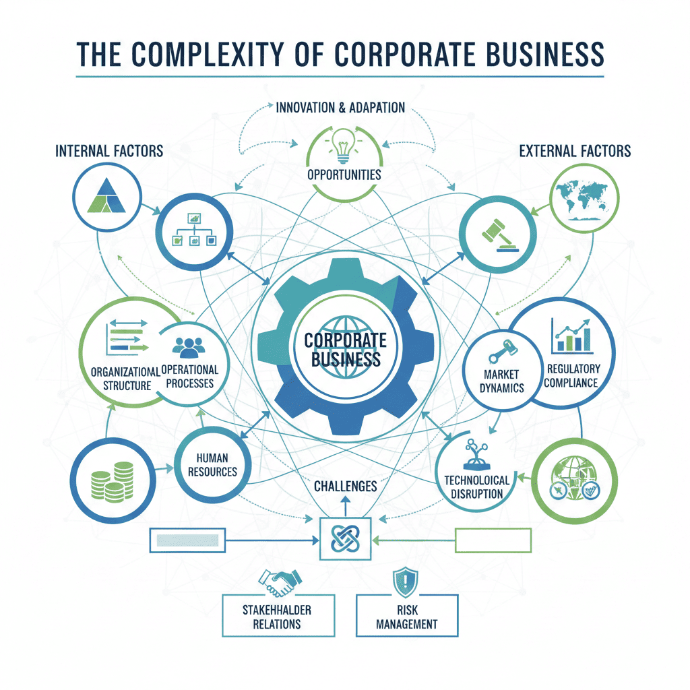

When Operational Complexity Increases

As operations grow and span across multiple locations, organizations face increasing challenges such as:

- Large and fragmented material master data

- Duplicate and obsolete spare parts across sites

- ERP systems that exist, but are not fully trusted

- Maintenance and procurement processes that rely heavily on manual workarounds

- High operational risk caused by inconsistent data and system misalignment

Without proper structure, digital systems become transactional tools rather than strategic enablers.

SCHEDULE TRAINING

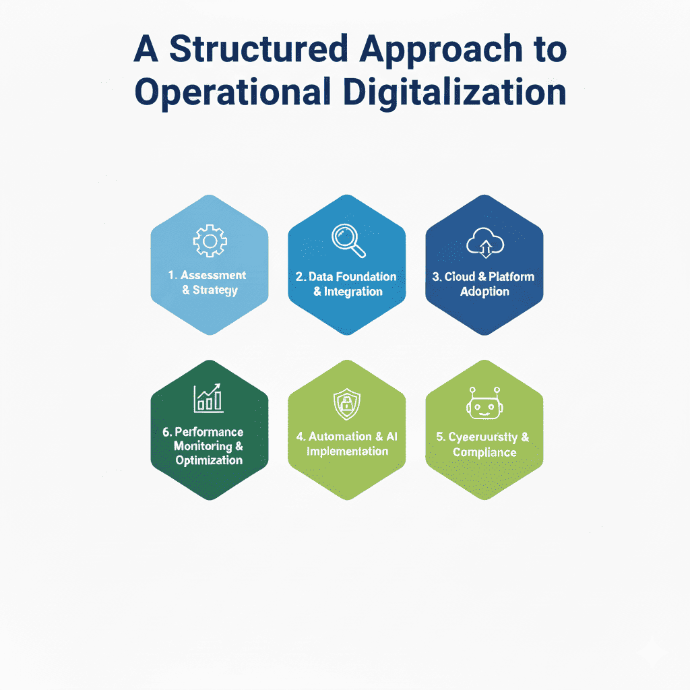

A Structured Approach to Operational Digitalization

Effective digitalization requires more than software adoption. It requires alignment between data, processes, and internal capability.

Our training portfolio addresses these three critical pillars:

- Structured and governed operational data

- ERP functionality aligned with real operational workflows

- Internal capability to sustain and extend digital systems

SCHEDULE TRAINING

Our Training Portfolio

Each training can be taken independently or as part of a structured learning path.

Material Cataloguing Training

Establishing Reliable and Governed Material Master Data

This training focuses on building a structured material catalog that supports maintenance, procurement, inventory, and engineering operations at scale.

Key Focus Areas:

- Material classification and standardization

- Definition of technical and MRO material attributes

- Prevention of duplicate and obsolete materials

- Data governance, approval workflows, and ownership

- Alignment between engineering, maintenance, and supply chain data

Outcomes:

- Improved visibility of spare parts across operations

- Reduced inventory redundancy and uncontrolled growth

- Strong foundation for ERP utilization and analytics

- Increased trust in material master data as a single source of truth

MORE INFORMATION

Odoo Functional Training

Aligning ERP Functionality with Real Operational Workflows

A hands-on functional training focused on ensuring ERP systems accurately reflect operational reality — supporting maintenance, inventory, procurement, and decision-making processes.

Key Focus Areas:

- Asset and maintenance lifecycle management in ERP

- MRO procurement and inventory flow

- Integration between material master data and operational processes

- Cross-function process alignment

- Operational reporting for better planning and control

Outcomes:

- Higher ERP adoption and system reliability

- Reduced dependency on manual processes and workarounds

- Improved coordination across functions and locations

- ERP positioned as a trusted operational system

MORE INFORMATION

Software Development Training

Building Internal Capability to Sustain and Extend Digital Systems

This training equips teams with the capability to develop, customize, and maintain digital solutions that evolve alongside operational needs.

Key Focus Areas:

- Understanding ERP architecture and customization principles

- Developing extensions without disrupting core systems

- System integration with other operational platforms

- Secure, maintainable, and scalable development practices

- Effective collaboration between IT and operational teams

Outcomes:

- Reduced dependency on external vendors

- Faster response to operational and business changes

- Sustainable digital systems that grow with the organization

- Strong internal ownership of digital solutions

MORE INFORMATION

A Structured Learning Path

Together, these trainings form a complete operational digitalization capability:

Material Cataloguing Training

Ensures data accuracy and consistency

Odoo Functional Training

Ensures systems reflect real operational workflows

Software Development Training

Ensures long-term adaptability and scalability

What Organizations Gain

This integrated approach enables organizations to move from fragmented systems toward structured, reliable, and scalable digital operations.

Reliable Operational and Maintenance Data

Operational and maintenance activities are supported by structured, consistent, and trusted data across systems and functions, reducing ambiguity and rework.

Stronger Control Over Inventory and Spare Parts

Improved visibility and governance of spare parts enable better inventory planning, prevent duplication, and reduce unnecessary stock accumulation.

ERP as a Trusted Operational System

ERP systems evolve from transactional tools into a reliable single source of truth that supports daily operations, planning, and cross-function coordination.

Reduced Operational Risk from Poor Data Quality

Clear data standards and governance significantly lower the risk of downtime, procurement errors, and maintenance delays caused by inaccurate or inconsistent data.

Better Decision-Making Through Structured Systems

Management and operational teams gain access to reliable, structured information that supports faster, more confident, and data-driven decisions.

Scalable Foundation for Multi-Site Operations

Standardized data structures and aligned system processes enable consistent operations across multiple locations while maintaining local operational flexibility.

Trusted by

-

And many more -

Schedule Free Consultation

Share your requirements or inquiries with us.

Our team is ready to provide professional support and tailored solutions aligned with your operational standards.

Email :

Phone/Whatsapp :

Head Office :

Jl. Panemu No. 01, Kalisoka, Margosari, Kec. Pengasih, Kab. Kulon Progo, Daerah Istimewa Yogyakarta 55652