Material Cataloguing for Mining Industries

Streamline your mining spare parts management with clean, standardized data across multiple sites.

Expert Material Data Management for Mining

Our material data services help mining operators manage complex MRO and spare parts data across fleets, plants, and remote sites.

Panemu works with mining companies to design practical, tailored approaches that:

Clean up and standardize existing spare parts data

Support new projects, brownfield, and expansion sites

Build a reliable material master as a foundation for ERP, EAM, and planning systems

You can engage Panemu for a focused scope to fix your most critical issues, or as an ongoing partner to build and maintain a strong data foundation in your mining operations.

We Understand the Mining Industry

Mining operations are asset-intensive, geographically dispersed, and heavily dependent on reliable MRO data. From haul trucks and shovels to crushers, conveyors, and processing plants, every equipment failure depends on the availability and accuracy of spare parts data.

Our team understands:

How mining operations structure fleets, plants, and workshops

The typical pain points in stockrooms, procurement, and maintenance planning

The data requirements of mining ERPs and CMMS systems (SAP, Oracle, Odoo, Maximo, etc.)

The realities of working with multiple OEMs and contractors across sites

This understanding shapes how we prioritize, design, and deliver cataloguing and SCS solutions for mining clients.

SCHEDULE CONSULTATION

Use Material Data to Unlock Value in Mining

Whether in day-to-day operations or during major shutdowns, missing or incorrect material data directly affects:

Data Problem

|

Mining Impact

|

Panemu Solution

|

Value Unlocked

|

Missing/wrong parts data

|

Repair delays + equipment downtime during pit operations

|

Structured cataloguing + SCS® workflows

|

Reduced inefficient processes

|

Duplicate inventory

|

Unnecessary spend on same parts ordered multiple times

|

Intelligent de-duplication (20-30% reduction)

|

Avoid over-purchasing similar items

|

Poor descriptions & coding

|

Locked capital in slow-moving/obsolete stock

|

ISO 8000-compliant standardized descriptions

|

Minimize production impacts from missing parts

|

Inconsistent site data

|

Reduced productivity for maintenance, warehouse, procurement teams

|

Multi-site hierarchies + reliable master data

|

Improved decision-making with accurate stock/usage info

|

A Strong Material Data Foundation Reduces Operational Risk In Mining By:

Improving visibility of critical spares and their completeness

Supporting planning accuracy for shutdowns and planned maintenance

Enabling better analysis of spend, usage, and stock levels per asset or site

Providing traceability for safety, quality, and regulatory requirements

Accurate, well-structured material data allows you to organize items in a clear hierarchy and classification, aligned with your fleet, plant, and process structure.

Panemu’s services can work with relevant standards and classification systems such as UNSPSC, NATO/NSN, and other MRO schemes, and can be aligned to mining asset and maintenance standards where required.

REDUCE OPERATIONAL RISK NOW

Why Mining Companies Choose Panemu?

1. Deep Mining Equipment Knowledge

Understand mining equipment, component structures, and typical failure modes across haul trucks, crushers, and processing plants.

2. Proven MRO Cataloguing Methods

Built cataloguing methods, rules, and workflows specifically designed for mining MRO challenges.

3. ERP/EAM Data Expertise

Know the exact data your ERP, EAM, and planning systems need to work correctly (SAP, Oracle, Maximo, Odoo, etc formats).

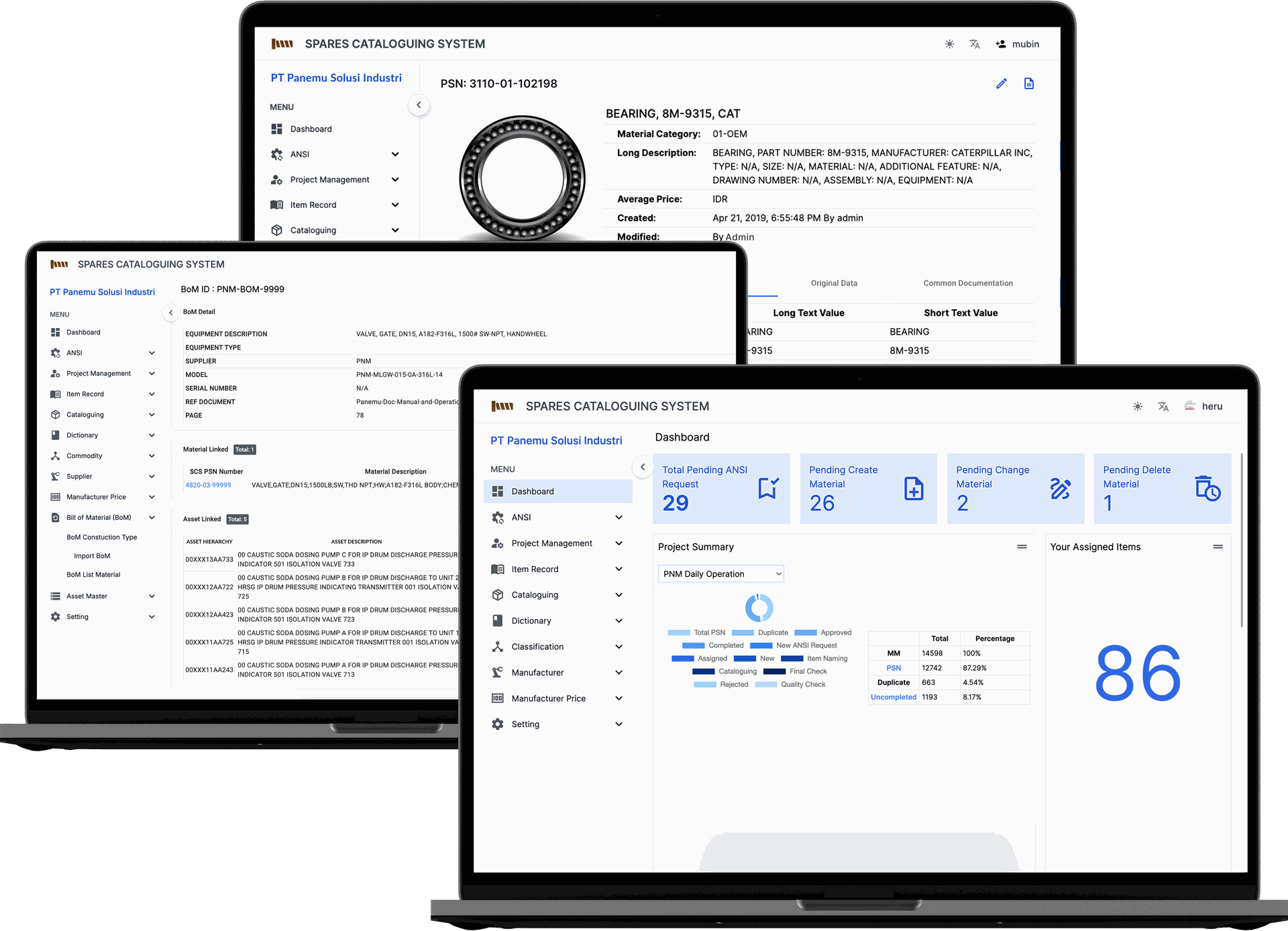

4. SCS® + Expert Cataloguers

Combine experienced cataloguers with SCS®, our dedicated cloud cataloguing platform for multi-site operations.

START EVERYTHING NOW

Panemu’s Mining Data Services

Panemu End-to-End Services :

Data Cleansing Services

Remove duplicates, normalize descriptions, and fix inconsistent coding.

Data Enrichment Services

Add missing attributes, manufacturer details, and technical characteristics.

Ongoing Cataloguing Support

Support for new items, new projects, and new suppliers through SCS® and cataloguing teams.

Training and Governance

Train internal teams and establish rules so data quality is maintained over time.

Our operating model is flexible:

You can fully outsource cataloguing work to Panemu, integrate our team with yours, or use a hybrid approach that evolves as your needs change.

Is Panemu the Right Fit for Your Mining Operation?

Panemu delivers reliable spare parts data management without requiring large internal teams.

- Multi-site operations: Mines, plants, remote sites with 10K+ spare parts

- ERP/CMMS reliant: SAP, Oracle, Odoo, or similar MRO systems

- Limited internal resources: Improve data without large cataloguing teams

- SCS® + expertise needed: Platform plus mining specialists for governance

- Complete solution: Tools, services, and processes for ongoing control

You receive consistent, high-quality material masters faster with less disruption than in-house efforts.

LET'S TALK TO US

Free Data Quality & Inventory Analysis — Before You Begin

Struggling to understand why your material data isn’t performing the way it should? Before you start full-scale cataloguing, Panemu can help you uncover the key issues holding your organization back.

What You Get With Our Free Analysis

✔️ We analyze a 70% sample of your current inventory data

✔️ Identify data quality gaps like missing attributes, duplicates, and inconsistencies

✔️ Highlight opportunities for inventory optimization, efficiency gains, and cost savings

✔️ Short report with actionable insights — so you know exactly what to fix first

This isn’t just data review — it’s your roadmap to building a clean, standardized, and operationally ready catalog.

Our expert team helps you see the real challenges before investing in full cataloguing.

Ready to See What’s Really Inside Your Data?

FREE CONSULTATION & DATA ASSESSMENT

Book your free analysis now — and get insights that make your cataloguing process smoother and more impactful.

Next Step Talk to the Panemu Team

If you are want to strengthen the material data in your ERP or CMMS, we can help you plan where to start and what to prioritize.

Get in touch with our team to discuss:

Your current challenges with spare parts and material data

The systems and sites you want to improve

The level of support you need (project-based, ongoing, or hybrid)

Contact Panemu to explore how cataloguing services, SCS®, and training can support your mining operations.

We are trusted by

-

And many more -

COMPLETE MATERIAL CATALOGUING TOOLS

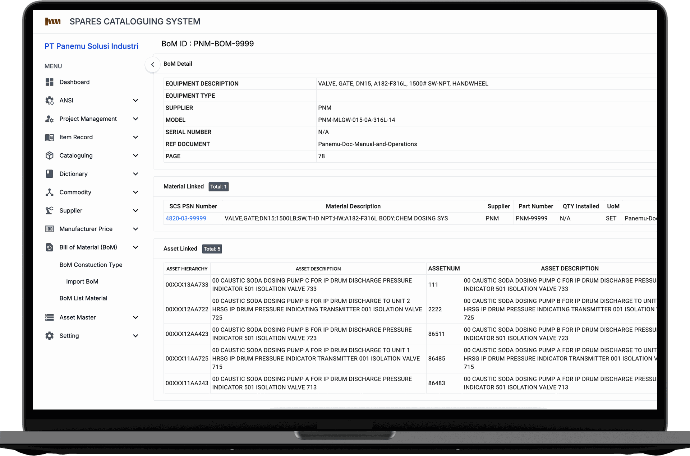

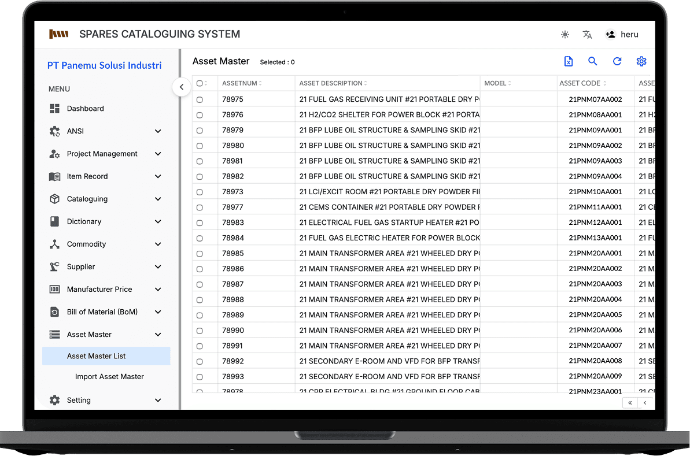

SPARES CATALOGUING SYSTEM®

SCS® is Panemu's specialized platform for material cataloguing and data management. Designed for asset-intensive operations, it provides structured workflows for data cleansing, standardization, and ERP preparation. SCS® helps maintain consistent material master data across teams and sites.

Key SCS® Features:

Structured workflows for step-by-step cataloguing with quality checkpoints

Multi-user role-based access for warehouse, planners, and procurement teams

Various dictionaries (UNSPSC, NATO/NSN, manufacturer codes)

Multi-project support for different sites, plants, or equipment fleets

Customizable fields to match your specific standards and processes

Direct ERP exports (SAP, Oracle, Maximo, Odoo) with validated templates

Cloud-based access for remote teams with high availability

Alternate parts tracking and superseded item management

Schedule Free Consultation

Share your requirements or inquiries with us.

Our team is ready to provide professional support and tailored solutions aligned with your operational standards.

Email :

Phone/Whatsapp :

Head Office :

Jl. Panemu No. 01, Kalisoka, Margosari, Kec. Pengasih, Kab. Kulon Progo, Daerah Istimewa Yogyakarta 55652