As a cataloger, you must realize how important an efficient and accurate supply cataloging system is in running a company's operations. However, we often face challenges in managing and using the Supplier Code and Part Number effectively. This article will invite you to explore solutions and best practices in optimizing the use of Supplier Code and Part Number in supply cataloging. By understanding the importance of this aspect, you will be able to increase the efficiency and effectiveness of your company's cataloging system.

I. Definition and Role of Supplier Code in Supply Cataloging

Supplier Code is a unique identifier given to each supplier or vendor involved in your company's supply chain. In the context of supply cataloging, the Supplier Code functions as a foundation in managing data and information related to suppliers. By using the right Supplier Code, you can efficiently identify, track and manage transactions. Not only that, the Supplier Code also simplifies the process of updating data and monitoring supplier performance.

II. Part Number: Key in Inventory Identification and Management

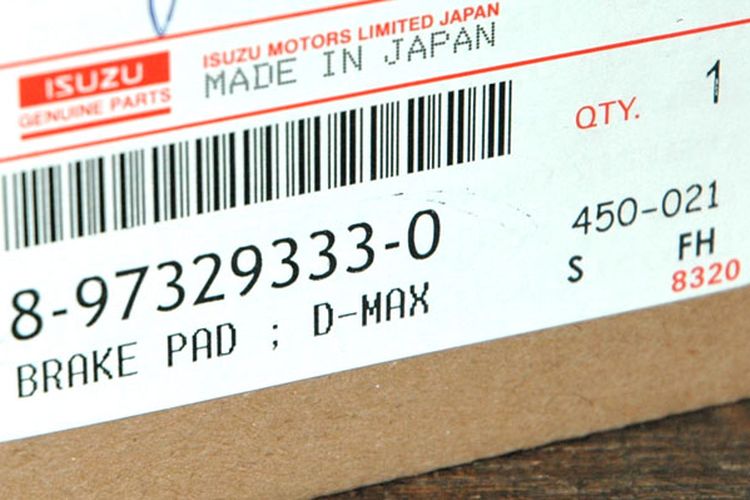

sample of spare part number, source

Part Number, or part number, has an important role in identification and inventory management. Each component, part or product in the supply cataloging system needs to have a unique Part Number. By using a well-structured Part Number, you can avoid confusion and errors in stock management and component replacement. The importance of using the correct Part Number should not be ignored in an effort to increase the efficiency of the cataloging system.

III. Advantages of Optimizing the Use of Supplier Code and Part Number

- Operational Efficiency

By using the right Supplier Code and Part Number, you will reduce the time needed to find and manage data related to suppliers and components needed. - Data Accuracy and Consistency

A consistent and well-structured Supplier Code and Part Number will minimize errors in data management, thereby increasing the accuracy and reliability of information in the cataloging system. - Cost Savings

By using an effective Supplier Code and Part Number, you will be able to optimize inventory management, reduce the risk of double procurement, and avoid unnecessary excess stock. - Flexibility in System Development

With standardized use of Supplier Code and Part Number, you will have a strong foundation for developing more complex cataloguing systems, such as integration with RFID or barcode technology.

Read more important article :

Rules in the Supply Cataloguing System in Companies that Must Be Understood Practical Steps to Begin the Supply Cataloging Process Understanding Supply Cataloging: An Important Foundation in Supply Chain Management The Best Strategy to Build a Reliable Supply Cataloging System

IV. Best Practice Implementation in Using Supplier Code and Part Number

- Establishing a Consistent Supplier Code

Defining a consistent and easy-to-remember Supplier Code will help facilitate supplier identification and minimize the risk of errors in recording transactions. - Application of Standard Part Number

Adopting industry-recognized standard Part Numbers, such as the International Standard Book Number (ISBN) for books or the European Article Number (EAN) for consumer products, will facilitate component search and identification. - Use of an Integrated Database Management System

Implementing an integrated database management system will facilitate the updating of Supplier Code and Part Number data in real-time, so that the information presented is always accurate and up-to-date. - Training and Consultation with the Cataloger Team

Involving a team of catalogers who are reliable and experienced in managing Supplier Code and Part Number will help increase understanding and implementation of best practices in your company's cataloging system.

V. Conclusion

In running an efficient and accurate supply cataloging system, the use of Supplier Code and Part Number is a crucial aspect that needs to be optimized. By adopting best practices and proper implementation, you can improve operational efficiency, data accuracy and cost savings. However, to achieve optimal results, it is important to involve a reliable team of catalogers and consider the best solutions offered by Panemu.

CLICK HERE for more information about SCS

Panemu is a trusted solution in supply cataloging, with the best application called SCS (Spares Cataloging System). SCS adopts the ISO 8000 data quality standard, the NATO Supply Classification, and the NATO Codification System codification system and the United Nations Standard Products and Services Code (UNSPSC). With complete features, such as data cleansing, data duplication checker, and data duplication removal, SCS can be customized according to the needs of the system implemented in your company. A reliable team of catalogers from Panemu is ready to help implement and process the Supply Cataloging System with high accuracy. Don't hesitate to contact the Panemu team by telephone or WhatsApp HERE or access OUR WEBSITE to find out more about us, or scs.panemu.com to get information regarding SCS and implement the best solutions offered by Panemu.